Transformer Cores

Description

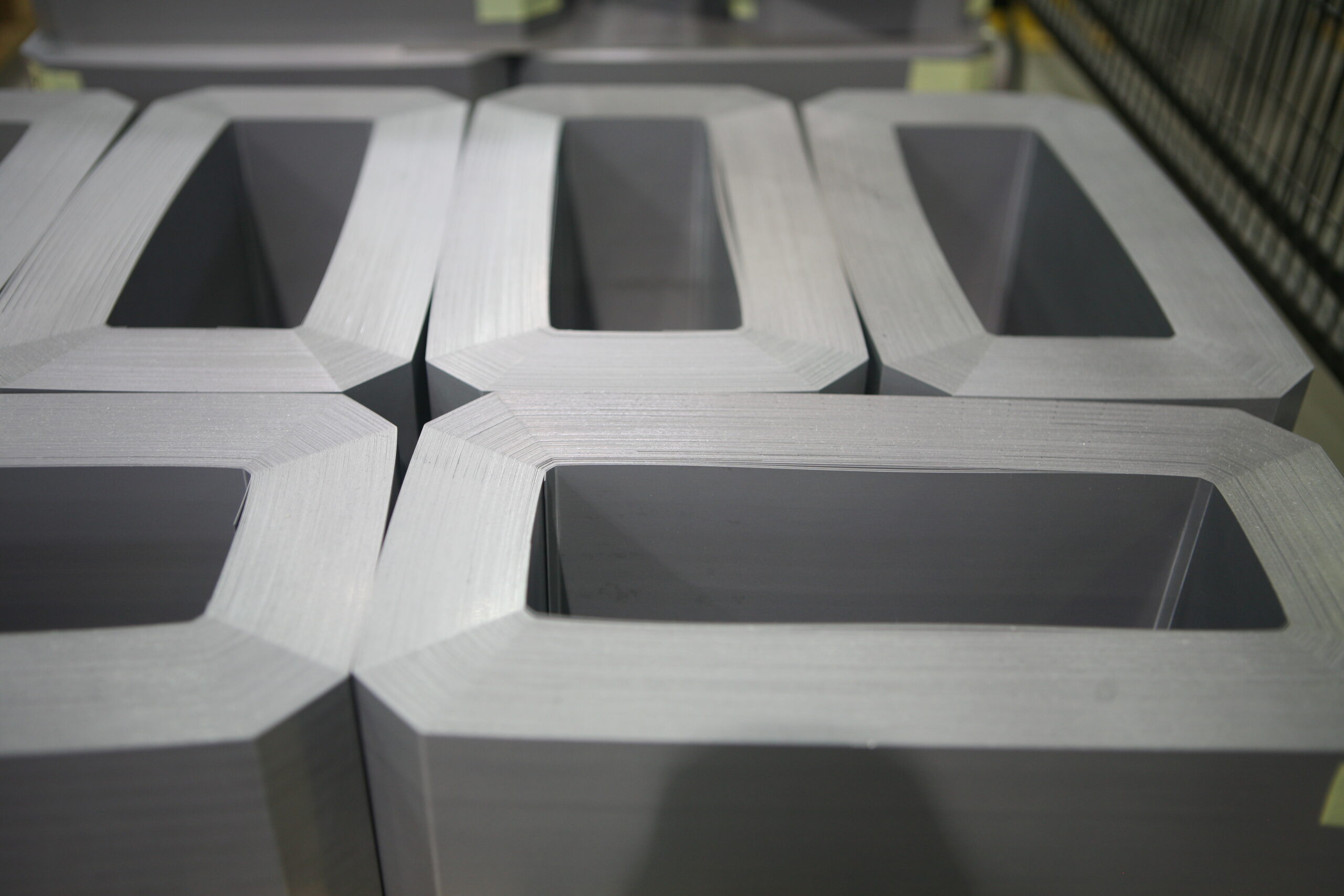

We manufacture coiled transformer cores from sheet metal in thicknesses:

- 0.23 mm

- 0.27 mm

- 0.30 mm

- 0.35 mm

Zastosowanie i korzyści

Applications

Wound cores are widely used as continuous magnetic circuits, which means they are circuits without an air gap created by cutting the core. This type of magnetic circuit has the best magnetic properties. They are achieved by more extensive use of anisotropic magnetic properties of sheets and owing to the beneficial impact of the shape of the magnetic circuit on the magnetic flux.

Benefits

- High quality and manufacturing precision of each core.

- Fast and easy core assembling (interlacing)

- The ability of any size ordering with lead time shorter than that of the cores made in a different technology.

- Low specific loss resulting from the diverging air gap, incomparably better than lamination cores or step lap cores.

- Thanks to the lower magnetic parameters, the core mass in the transformer is reduced or the amount of copper is in the coiling is lower and, additionally, the delivery costs of the finished product are lower.

- Attractive price, lower than that of C- or E-cores.

- Thanks to the application of the laser treated sheets processed by Stalprodukt, core annealing can be

eliminated, which reduces the cost of the core itself. - Wide scope of applications, using the unicores, one can produce transformers of power capacity of up to 10 MVA.

Files to download

Gallery

Contact

Contact form

Certificates

English

English